Installation and commissioning

● All equipment provided in the contract shall be installed and debugged by our company: after signing the contract, our company shall determine the specific installation location of the equipment in the shortest time, and provide the equipment foundation drawing within 5 working days after the contract comes into effect; Before installation, commissioning and debugging, your company should strictly prepare the equipment foundation according to the requirements of the equipment foundation drawings provided by our company, ensure that after the installation site, the engineer will carry his own tools for the installation and debugging of the equipment, and be responsible for completing the installation, debugging, technical indicator testing, training, acceptance and delivery of the equipment within 10 days;

● The relevant expenses for installation, commissioning and assigned personnel shall be borne by our company.

Logistics transportation

● The place of delivery is your company‘s installation site;

Standard packaging, suitable for long-distance bus transportation, moisture-proof, rust proof and shockproof; It is applicable to overall hoisting, and the hoisting center of gravity and hoisting position shall be indicated;

● Transportation mode: automobile transportation. Our company is responsible for freight and insurance;

● Each packing case shall be attached with a detailed packing list and quality certificate; Equipment instructions and other documents and data shall be attached in the packing box. The packing list is outside the packing box, and the certificate of conformity is inside the packing box.

Equipment acceptance

a. Acceptance criteria: the acceptance shall be conducted according to the technical agreement in the contract signed between our company and your company.

b. Final acceptance

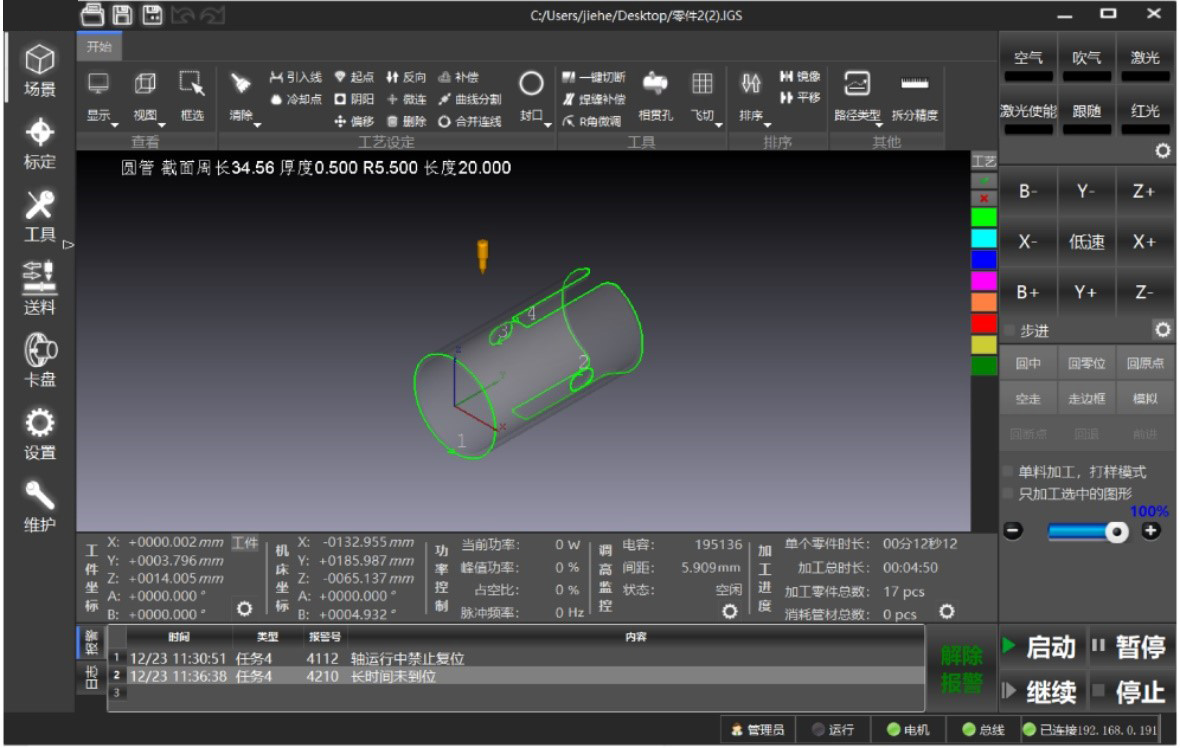

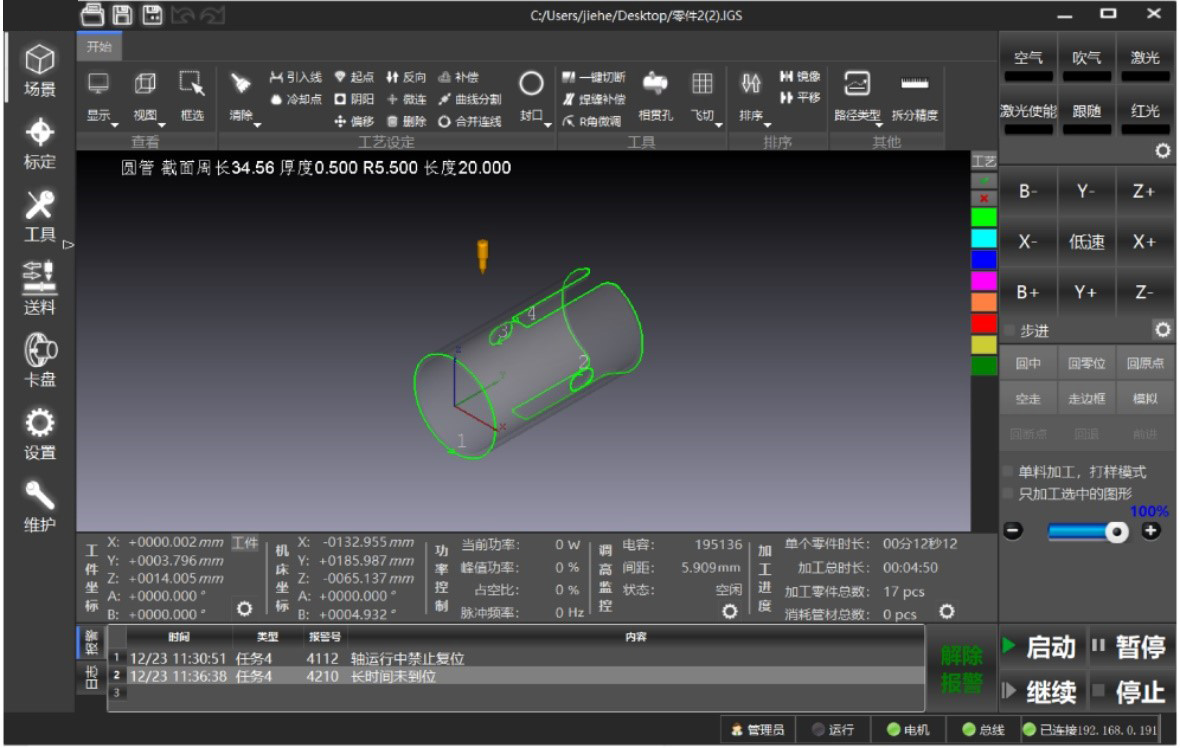

● After the installation, commissioning and self inspection of the equipment, our company will carry out acceptance on the buyer‘s site, including the inspection and acceptance of the quantity, model, specification, function, technical indicators, etc. of all goods; Carry out laser cutting for typical samples approved by both parties;

● Both parties shall make acceptance records and evaluate the acceptance results. Performance assessment can only be carried out after both parties sign for approval.

c. Other instructions for final acceptance

● If the acceptance is interrupted due to the failure of site auxiliary facilities (power supply, surrounding environment, etc.) or the environment does not meet the requirements for normal operation of the equipment, the Demander shall immediately repair it to ensure that the equipment can work properly.

● In the process of acceptance, if the equipment is found to be missing, damaged or not in conformity with the contract terms and quality standards, our company will be responsible for making up and replacing, and the related costs arising therefrom shall be borne by our company.

Technical training

Our company is responsible for free technical training. After the installation and commissioning, the operators of your company shall receive at least 5 days of technical guidance and training until they can master the technical principles of the equipment structure and the correct programming, operation, inspection, repair and maintenance of the equipment

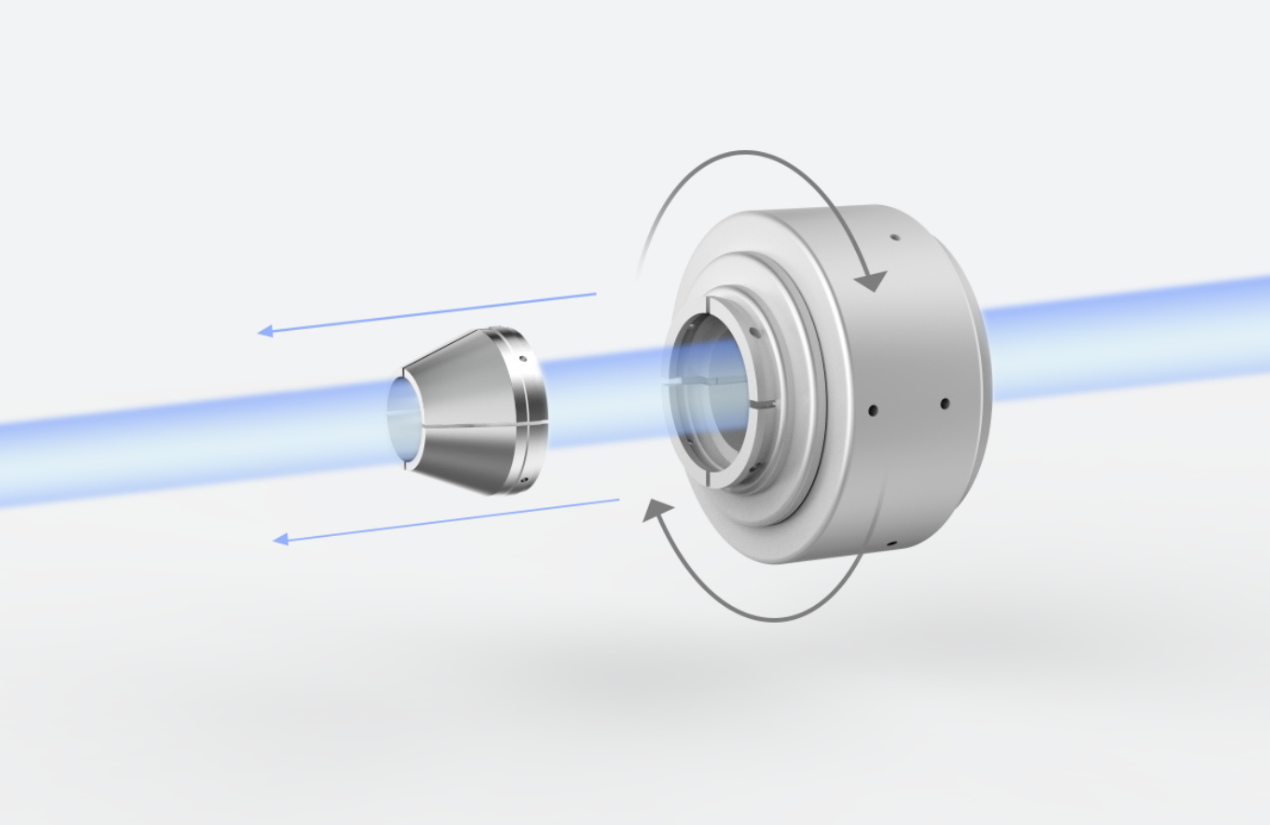

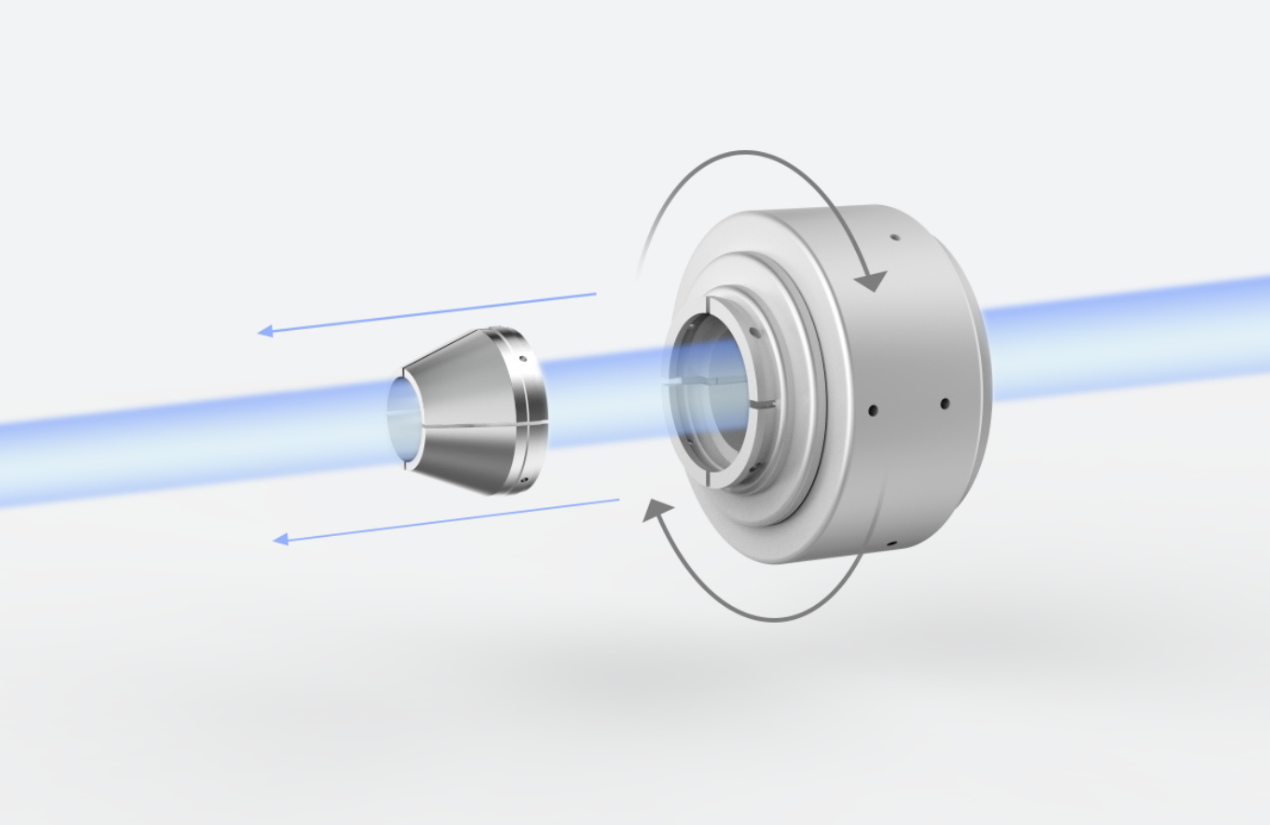

The main training contents are as follows: structure and principle of equipment; Programming, operation, maintenance and general fault diagnosis of equipment; Laser processing technology; Common faults of equipment and troubleshooting methods (including mechanical, electrical and pneumatic parts); Laser processing safety education, etc

after-sale service

1. After the final acceptance of the equipment is strictly signed, the warranty period of the whole machine is one year;

2. In case of quality problems of system parts during the warranty period, our well trained service engineers will provide telephone or on-site services at any time. For any damage or damage caused by the quality of the equipment, our company is responsible for replacing parts and services free of charge, except for conventional consumables (such as external operating optical fiber, optical lens, cutting nozzle) and those who are responsible for the user‘s illegal operation accidents;

3. During the warranty period, after receiving the maintenance notice from the Demander, we will assign a special person to follow up and make a reply within 2 hours. If the failure cannot be eliminated by phone, WeChat or fax, our technical service personnel can arrive within 24 hours (excluding the travel time);

4. Beyond the warranty period, our company still provides the demander with extensive and preferential technical support services, regular maintenance of complete machines and auxiliary machines and supply of spare parts; Provide the whole process maintenance service for the products provided, and provide daily consultation and guidance related to the equipment at any time, as well as information and data on equipment improvement and maintenance technology;

5. Our company has sufficient spare parts to provide technical and spare parts services to the demander in time to meet the needs of equipment operation and maintenance;

6. Our company regularly arranges project engineers to visit the user‘s site for free technical return visits;

7. In the process of developing new varieties and using new technologies, our company provides relevant technical services and technical support (such as software upgrading services) for free.